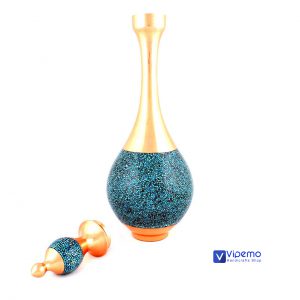

Sangab – Size 4

€270.00

- Height : 18.8 cm

- Usage : Decorative Crafts, Persian Gift

Firooze Koobi (Turquoise inlaying) is an old Iranian process of making wares and jewelry by implanting small pieces of turquoise stone in the surface of metals such as copper, brass, silver or bronze.

The product is one of the most beautiful Iranian artworks dating back to at least half a century ago. Iranian artisans use turquoise in various forms of art including calligraphy and handicrafts.

- Description

- Additional information

- Reviews (0)

Description

Turquoise Tibet using one of the best decorations of Turquoise Neyshabur, is a beautiful and captivating artwork.

These containers, which in the past were made of tufted glass or crystalline crumbs, were made of copper and turquoise, Neyshabur, whose use of copper in view of the properties of copper in protecting human health increases the durability and durability of the product.

All the stones used in this product are placed and pasted.

Turquoise Inlaying both on jewellery and containers includes a copper, brass, silver, nickel or bronze object on parts of the surface of which small pieces of turquoise are set in mosaic fashion thus giving the object a special glamour. The production of Turquoise Inlaying includes two general stages:

Goldsmith

Goldsmith includes the making and preparation of the object intended for Turquoise Inlaying using one of the metals indicated above. This is done by a goldsmith using hands, press machine or both. After the object is formed generally, be it a piece of jewellery or a container, the part to be turquoise inlaid is demarked and a thin metal strand (of the same material as the metal used in the fabrication of the object) called “kandan” is placed around and soldered onto it. This part around the intended form is a so-called wall standing two or three millimetres above the surface of the container. This is usually done by or sometimes the turquoise inlayer himself. If the part prepared for Turquoise Inlaying takes up too much of the surface with an empty looking background, strands of the same metal are used to place smaller patterns of decorative nature (such as flowers, bushes, etc.) inside it and soldered again. This both makes the work more beautiful and makes the turquoise inlaid surface stronger.

Turquoise Inlaying

First of all, the turquoise inlayer buys waste turquoise chips from turquoise forming workshops or turquoise mines in Mashhad, Neishabour or Damghan. Since such turquoise chips are usually accompanied by some earth and ordinary stone chips, they are first separated and cleaned. Then, the turquoise chips are graded based on their sizes so the right size turquoise chips are used in making each Turquoise Inlaying object in proportion to the surface area. In the next step, the object is heated (to about 30oC) and, while heating, a “walnut lac” is sprinkled onto the parts that have to be turquoise laid so that the lac powder is almost melted and covers the intended surface.

While the lac is still soft and sticky on the object surface, some of the turquoise chips that were prepared before based on their size are placed on the work surface. The chips must be placed in a way so that no space is left between them as far as possible. In order to fill the possible gaps between turquoise chips, temperature is added (to about 40oC) and some more lac powder is sprinkled onto the chips until the lac layer is softened to a melting form, and then try to fill all the spaces by adding smaller turquoise chips, or, as they say, the chips sit well on the surface. This is usually done by pressing the turquoise chips by hand onto the surface so that they stick fast to it. After the object is cooled, the lac covered parts become rigid.

After that stage, the parts covered by lac and turquoise chips are polished with emery so the extra lac and little raised parts of the chips are flattened. That is the stage where the colour of the turquoise chips becomes visible as turquoise and that of lac as black (or dark brown) in the spaces between the chips. After this stage is completed, if there is still some fallouts in some parts of the work, the object is heated again, and the empty parts are restored with small turquoise chips and lac.

Then, the surface is polished and honed again. The restoration is sometimes done with a type of turquoise coloured putty that is prepared with “mol” mud, oil and lapis paint. The final stage of Turquoise Inlaying is burnishing which is done in two stages itself. The first stage consists of burnishing the metal parts which is done at a goldsmith or machining workshop where the opaque layer that is formed on the metal parts during Turquoise Inlaying is removed with hand tools or a machine blade, and then, those parts are polished so the metal becomes shiny. The second stage consists of burnishing the turquoise inlaid product. After polishing the metal parts of the object, the work is returned to the turquoise inlayer’s workshop where the turquoise inlaid surface is polished with olive or sesame oil so that part becomes shiny, too.

A Turquois Inlaying craftsman employs different tools and devices for different stages of the job mostly including dies, hammers, drills, natural gas and gasoline torches, pincers, pliers, forceps, different metal pipes tweezers, files and emeries. The most important point in Turquoise Inlaying is the correct installation of turquoise chips on the metal so that it is strong enough and the chips do not come off while burnishing the work. The other important point is that a piece of turquoise inlaid work will be of more artistic value if the turquoise chips are installed more regularly in close contact, i.e. without space in between.

Additional information

| Dimensions | 14 × 14 × 18.8 cm |

|---|

Reviews

There are no reviews yet.